Teledyne Reynolds 是一個全球性供應商,提供工程解決方案,系統集成應用,軍事和商業應用的設計,開發和製造 – 提供卓越的性能和可靠的產品,通過AS9001,ISO 9001和AS140001認證,以及質量保證認證,包括支持SC21 , ISO9001 , ISO9100 , ISO14001認證。

| 高壓軍用電纜組裝和連接器的主要功能包括: |

|

高電壓(軍用電纜組裝,連接器和電線,元件和電陶瓷)

高壓電纜組裝,定制設計和製造能力與一系列專門的高壓連接器和電線。Teledyne Reynolds還提供火花隙,高壓雲母電容器和專門的電子陶瓷產品。應用範圍包括醫療,工業,裝甲車,商用和軍用無人平台和彈藥的管理。

靈活的,半剛性電纜定制產品

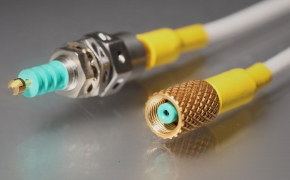

| 靈活的半剛性電纜定制產品是一個高度專業化的設計,製造和測試能力,其中包括了在任意組合高低壓,光纖,數據, RF和視頻鏈接,以滿足精確的互連要求毫不妥協。 如果一個定制的連接器被要求,Teledyne Reynolds有必要的設計技能和多年的經驗,生產所需要的精確解決方案。如果您只需要Teledyne Reynolds的製造和測試能力,請聯繫Teledyne Reynolds構建到打印解決方案。對於軍用市場,Teledyne Reynolds提供快速ODM能力。除了生產電纜組裝,Teledyne Reynolds公司提供電纜的一個新的水平整合成子組裝,以提供經過全面測試的產品。這種能力也是定制的設計,製造和試驗或建製到成品。 |

射頻和微波電纜組裝

| 射頻和微波電纜組裝(柔性,半剛性,剛性,自定義)定制和型錄的指定範圍內的射頻和微波電纜組裝運行到最高50GHz的的。Teledyne Reynolds的高性能柔性電纜組裝的設計,以滿足電氣和機械性能由系統或測試與測量應用的要求。

半剛性電纜範圍通常選擇其卓越的屏蔽和插入損耗 – 使用CAD和自動折彎設備,以確保精密成型組裝培訓的技術人員。自定義電纜產品也都具備,包括增加軟或硬鎧裝,抵抗惡劣環境和具體的射頻特性。 |

點火和軍械的電纜,雷管,點火裝置和電子產品包裝

| 點火和軍械的電纜,雷管和消防設置一個高度專業化的一系列啟動和軍械能力和產品。一個可靠的高壓電線電纜範圍內,這是電子束焊接的地方或EFI啟動用於每個爆炸引發體系的重要組成部分。包含電子束和EFI雷管廣泛的範圍,而且Teledyne Reynolds能夠開發特殊設備,以您的具體要求。 Teledyne Reynolds生產的電子束和EFI燃燒系統的完整產品線 – 設計為允許遠程布防和引發的射擊。 |

電子安全處理,布防和發射單元

Teledyne Reynolds還設計,開發和生產電子束和EFI的電子安全處理,武裝和發射單元的一個廣泛的範圍。

應用範圍包括:

- http://teledynereynolds.bentech-taiwan.com/_themes/ice/bull1_ice.gif); color: rgb(0, 53, 114); font-family: 新細明體; font-size: medium; line-height: normal;”>

-

採礦

-

海底勘探和生產

-

研究和開發方案

-

地球物理應用

-

軍事項目(如軍械處理)

-

商業用途(如拆遷)

連接器和線材的有效載荷和啟動應用程序空間(有效載荷和啟動應用程序)

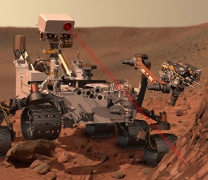

Teledyne Reynolds提供定制設計和指定目錄高壓電纜組裝,連接器和線材負載和啟動應用程序。

淨荷規格的互連解決方案,在Teledyne Reynolds自己的潔淨室生產,設計與有效載荷集成相結合,以滿足最嚴格指定的性能和環保要求。目錄的產品,如600SQ系列,提供了作為他們的數據或根據商定的驗收測試程序( ATP)的規定。還有一個設施很多樣品保留。Teledyne Reynolds還提供線纜組裝產品,以一批重大項目,包括:國際空間站, BEPI科倫坡和Arianne V。

|

|

連接器和線材的有效載荷和啟動應用航空電子互連解決方案

摘星

|

|

|

航空電子互連解決方案 – 高,低電壓,光纖光學,數據, RF和影像鏈接

Teledyne Reynolds高度專業化的設計,製造和測試能力,採用任意組合的高低壓,光纖,數據, RF和視頻鏈接,以滿足精確的互連要求。航空電子互連往往需要Teledyne Reynolds的程序設計人員在特定平台的解決方案的工作。除了生產電纜組裝,Teledyne Reynolds提供的電纜下一級融入子組裝,以提供經過全面測試的產品。誰的客戶只需要製造和測試能力都非常歡迎與Teledyne Reynolds構建到打印解決方案。對於軍用市場雷諾茲Teledyne公司提供管理快速轉身程序UOR能力的計劃。引入光纖的進入Teledyne Reynolds的航空電子設備的能力降低的質量和尺寸,並提高了性能,通過用等效的組裝相比,僅使用銅線。Teledyne Reynolds公司可以設計,製造和測試光纖電纜組裝作為獨立產品。

作為一個除了光纖的能力,通過使用終止與Teledyne公司雷諾海波連接器,其中包括了4.25Gbps的光纖/數字收發器的光纖電纜,Teledyne Reynolds可以提供解決方案,以提升地方互連需要提供更多的容量,增強的設計問題帶寬和現有的設備,但在空間和大眾之間的更高數據速率的能力是關鍵的考慮因素。

產品報導原文來自 militarysystems

|

|

|

|

| 高壓電線電纜 | 高壓單點接頭 | 高壓38999接頭 | 高壓多點接頭 |

|

|

|

|

| 高壓D型接頭 | 高壓光纖接頭 | 高壓陶瓷接頭 | 高壓電容 |

|

|

|

|

| 高壓放電管 | 高壓倍壓整流器 | 高壓訂製接頭 | 先進高壓接頭 |

|

|

|

|

|

|

|

|

|

|

|

|

|

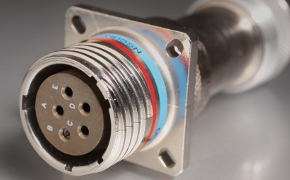

Reynolds Industries is known worldwide for continuously improving the performance level of high voltage connectors for more than 50 years. Reynolds leads the connector industry in the design and manufacture of connectors capable of operating reliably at altitudes up to 70,000 feet while exposed to temperatures as low as -55°C and up to +125°C. This high voltage expertise has been combined with our fiber optic capability to provide innovative, custom designed, fiber optic/high voltage/ hybrid connectors. |

|

Shown is a blindmate connector used to connect single mode optical fiber, signal and high voltage lines to an expendable decoy. Manufacture of these hybrid assemblies and the single mode termini using active alignment, is performed in our dedicated state-of-the art “white room.” |

|

A 50 KVDC, low corona, high voltage cable assembly designed by Reynolds for an electron gun. Reynolds Connector Products Division excels in the design and testing of connectors and cable assemblies having a low corona requirement. Testing is performed in Reynolds partial Discharge Test Laboratory with the most advanced equipment and corona detection techniques in the connector industry. |

|

|

|

|

|

|

|

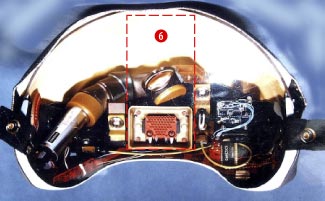

Pilot Helmet Mounted Display Components manufactured by Reynolds are integrated into a helmet mounted display system. These components, which include highly flexible wiring harnesses, connectors and Flex Circuits, provide high voltage , low voltage and signal lines to the display unit. The Flex Circuits provide the interfaces to the camera, display and tracker components. The connector to the helmet is very |

flexible to minimize pilot irritation and fatigue. 8,500 VDC is required by the display unit to provide a clear image to the pilot even in bright sunlight. The system must function at altitudes up to 70,000 feet and at temperatures of -40°C to +55°C. If the pilot is ejected, the connectors, which are explosion proof, disconnect quickly and automatically with a low unmating force. |

|

|

|

|

|

1. The Helmet Release Connector (HRC) permits the helmet to be shed in the event of inadvertent helmet loss during ejection. |

|

|

Reynolds Industries Electro-Ceramic Products Division is co-located with the connector Products Division in our Los Angeles facility. The three products shown are typical products designed, developed, tooled and produced by the Ceramic Products Division. 1. A high pressure, high current feed-thru sealed for 1000 psi differential pressure. The body/flange is 304 stainless steel. Electrodes are copper. Length is 12.75 in. Flange diameter is 3.75 in.

|

|||

|

||||

|

|

|

|

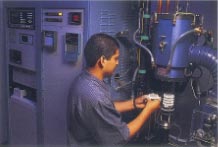

The manufacture of reliable ceramic-to-metal sealed devices requires not only precision furnaces but also a host of computer controlled production testers and inspection equipment. Following is a partial list of equipment not shown: -Evironmental hot/cold chambers – Mass spectrometer leak detector with 1X10-9 He/sec. maximum leak rate detection capability -70,000 foot simulated high altitude Hi-Pot tester to 100 KVDC The Electro-Ceramic Products Division also has available to it a model shop, a first class tool shop, additional environmental testing capability and the Quality Assurance department all located within the Los Angeles facility |

|

|

|

|

|

|

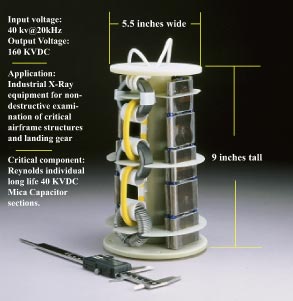

Reynolds Electronic Products Division manufactures ceramic-to-metal sealed gas tubes (spark gaps), transient protection systems, high voltage mica capacitors and voltage multipliers. The high voltage filter capacitor module shown to the left, represents the state of the art in the packaging of high voltage capacitors for military applications. The module, which is near monolithic, is replaceable by unmating the six high voltage lead assemblies and the mounting bolts on the base of the unit. Turret lugs and seven imbedded screw inserts allow the user to attach critical components to the exterior of the module for more efficient cooling and replacement. The module contains12 mica capacitor sections wound on Reynolds multi-spindle precision capacitor roll winding machines. Each of the sections are “burned in” to a rigorous specification developed jointly by Reynolds and the customer. Reynolds designed and packaged this unique capacitor module based on our customer’s requirements. |

|

|

|

In many situations, the use of voltage multipliers is the only realistic way to produce high voltages. Reynolds Electronic Products Division manufactures a family of voltage multipliers with output voltages ranging from 2.5 KVDC to the 160 KVDC X-Ray equipment shown on the right. Our voltage multipliers use only reconstituted mica as the dielectric. Mica, with a temperature capability of -55°C to +125°C with no derating, surpasses all competing technologies. Micapliers are used in a wide range of military and commercial applications. Typical applications are: CRT anode and focus supplies for airborne Electronic Flight Instrumentation Systems (EFIS), X-ray equipment, battle tank missile targeting systems and various ground missile launch systems. Reynolds designs voltage multipliers around the customers electrical and me-chanical requirements, constructs breadboard models for electrical testing and packages the design to the customers specification. |

|

|

|

|

|

.jpg) |

| RISI is a Reynolds subsidiary located in Tracy, California. RISI was incorporated in 1972 to design and manufacture explosive products primarily for military applications but quickly found applications in commercial blasting and oil exploration. Reynolds is the industry leader in the manufacture of explosive devices and systems using only secondary explosives. Most RISI products manufactured for the Aerospace/Defense industry are designed and developed by RISI to a customer requirement.

The Millisecond Delay Initiator shown at left, is an example of a product developed from a customers “wish list”. Containing only secondary explosives, the initiator can be ordered with a delay of up to 100 milliseconds in 1.0 millisecond increments from the time the electrical pulse is applied. This versatile product can also be initiated from shock tube, an Exploding Bridgewire Detonator (EBW) or an Exploding Foil Initiator (EFI). |

| The RP-503 is an all plastic case, sealed EBW detonator designed to function under water up to a depth of 10 feet. It is designed to provide similar explosive output as a #8 blasting cap with significantly less fragmentation. The detonator is provided with up to 100 feet of RISI’s rugged twin lead blasting cable attached.The output pellet is 454 mg of RDX. The initial pressing is 167 mg of PETN. Key performance parameters are: Threshold burst current:180 amps. Threshold voltage: 500 volts (approx.) Function time: 5.0 µ sec. max. |

|

.jpg) |

1 Plastic Bonded Explosive (PBX) |

2 EBW PETN |

| RISI has developed the capability for processing secondary explosives for improved handling, pressing and shock initiation characteristics over standard military specification materials. Quantity processing can be performed to a wide range of specific customer requirements. Photo 1 shows EFI HNS 1 10 times actual size. Crystal size is 12 m2/gram prilled with 5% Binder. The process results in plastic bonded explosive materials with significantly improved handling, pressing and pelleting characteristics. Photo 2 shows PETN 180 times actual size. Crystal size is 0.3 m2/gram. The process modifies the size and shape to improve its sensitivity to shock from an EBW or EFI. |

|

|

With production facilities in Newbury, England and Cwmbran , Wales, Reynolds Industries Limited is a leading European designer and manufacturer of connectors, cable assemblies and electronic component packaging for military and aerospace applications. The company also has a Microwave Products Division which designs and produces flexible and semi-rigid microwave cable assemblies and a range of microwave switching networks for the telecoms and military markets. |

|

|

|

FRONT: EFI SAU module and Slicline down-hole firesets for use at 170°C. MIDDLE: FM150 Firing Module, TA20 Hook-up Tester and FD201 portable fireset with built in delay function and a limitless daisy chain connection capability. BACK: FE106 multi-channel fireset. |

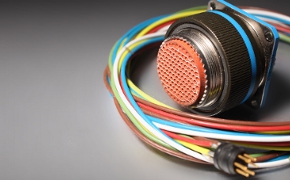

| A MIL-C-38999 connector conversion with HiMate high voltage lead assemblies, single mode fiber optic lines and low voltage lines combined to form a multi-mode cable harness. |  |

公司電話:+886-2-26958906

行銷專員:簡伊婉 (分機216): yvonne@bentech-taiwan.com

技術服務:朱柏建 (分機213): jonah@bentech-taiwan.com

.jpg)

.jpg)

.jpg)

Precision computer controlled temperature/time profiles within the hydrogen brazing furnace, are necessary to the manufacture of repeatable high strength and leak tight ceramic-to metal connectors and assemblies.

Precision computer controlled temperature/time profiles within the hydrogen brazing furnace, are necessary to the manufacture of repeatable high strength and leak tight ceramic-to metal connectors and assemblies.

.jpg)